Movies

AP-1500 30PM Automatic drilling and tapping station

Home » Our offer » Multipurpose and pillar drilling machines » AP-1500 30PM Automatic drilling and tapping station

|

Parametr |

|

Wartość |

|

Silnik wrzeciona |

obr./min |

1,5kW/1500 |

|

Obroty wrzeciona |

obr./min |

0-2400 regulowane bezstopniowo |

|

Posuw szybki w osi : X / Y / Z |

mm/min |

10 000 / 2000 / 2000 |

|

Długość / szerokość rolotoku podawczego |

mm |

2000 / 200 inne długości wg ustaleń |

|

Max skok podajnika |

mm |

1200 inne długości wg ustaleń |

|

Max szerokość detalu zależna od rozmieszczenia otworów |

mm |

75 (max 150) inne wielkości wg ustaleń |

|

Zacisk materiału |

|

Pneumatyczny |

|

Śruba kulowa |

|

Oś X i Y |

|

Rolotok odbiorczy |

mm |

1000 inne długości wg ustaleń |

|

Weight |

kg |

600 |

|

Układ sterowania |

|

Mitsubishi |

|

Zasilanie / sterowanie |

|

400V, 50Hz / 24V |

Technical Characteristics

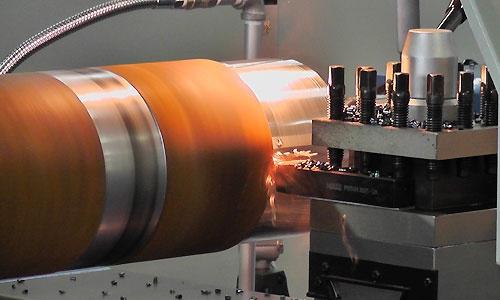

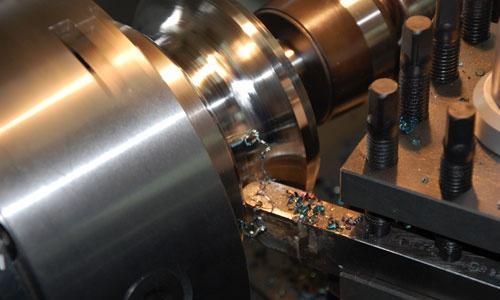

Automatic drilling and tapping station for long elements AP-1500 30PM

Automatic feeder for long elements model AP-1500 is intended for precise feeding of the long elements to the machining position, for example drilling boring counter boring, reaming and similar operations which require precision setting of their positions along and across the jobs. A material is fed by feeder driven by servo motor. The servo motor is operated by central computer with control of displacement by absolute digital linear readout. Feeder sleeve with clutched material is moved by given distance in time while vice on drilling machine is open. After given displacement is reached, vice on drilling machine is closed, spindle speed turned on and quill feed is on. Firstly, it moves with high speed, then the feed is on. It can be programmed on normal computer or directly on machines console panel. When the material is too long for one continuous movement, the material is locked on machines vice, feeders vice is opened and backs off by programmed length. After that the material is clutched in the feeders vice again, machines vice is opened and feed pursue normally, until movement range is out again or programmed work is done. This multiplication is controled intependetly by machines control computer.

Rotation speed and feed is correlated with each other by controllers computer. That allows to program in mm/rotation and in consequence tap with forced lead of thread. Foreign companies offering similar machines, use „mother screws” on spindle. Unfortunately it requires making and changing this mother screw for each lead, significantly increasing operation time. In our solution, all you need to do to change lead of the thread is write new value on machines control panel.

Digital control of spindle quill enables also for more economical drilling of cross sections, where after drilling through first side, quick traverse occurs until second side is close. Then normal feed is on again, after drilling is done, spindle quickly moves out of the material.

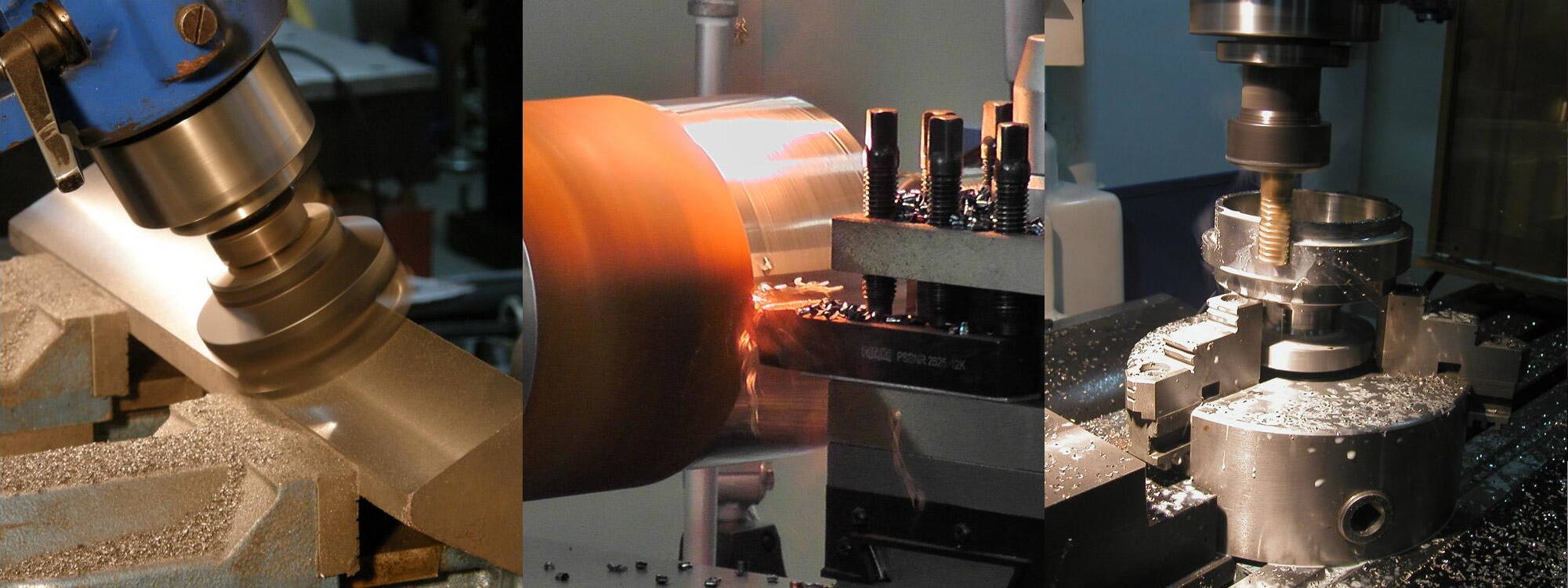

Important advantage of our machine numerically steered cross traverse of the machines table. In combination with properly designed feeder sleeve, it enables drilling holes to be placed at any suitable width. It also enables milling cross slots(„beans”). Solutions from another companies does not allow these possibilities.

Control unit of the machine, has software specially made for it, by TOP company. It is based on Mitsubishi hardware. This combination allows for quick, precise and highly repetitive manufacturing. It allows for control of 4 axis with axis synchronization function.

The precision and repeatability are acquired by Mitsubishis feeder drives, which control feeders motors. The machine remembers its position even after switching off.

Software enables intuitive and easy machine usage thanks to touch panel, that gives operator access manual and automatic mode. It also enables program edition with possibility of creating iterations of repeating elements of the program. For increased efficiency, in application you can find long-hole drilling, through-hole drilling and tapping. Programs, can be saved and uploaded on HMI or external USB drive. For service purposes, additional informations are displayed in SYSTEM. Software is available in English and Polish.

Most important advantages of our solution is:

- Allowing drilling ant tapping long elements, on smaller, cheaper more economical and more ecological machine.

- High accuracy of holes axis placement ( tolerance as low as ±0,01).

- Tapping with forced lead of thread increases accuracy of the thread, it also allows for tapping in low strength materials as well as hardmachinable ones.

- Possibility of drilling in X an Y axis with automatic travel onto drilling position. It gives additional cost reduction when machining multiple elements.

ZOBACZ FILM

ZOBACZ FILM